2-28-24 Driveshaft restoration service has been discontinued

Description: 1970-73 FORD Concours Driveshaft Restoration Service

Year: 1970-73

Model: Ford, Mercury

Engine: All with 3" driveshaft tube & 1330 series u-joints

Transmission Type: Manual & Automatic

Factory: All

Warranty: 1-year limited

Turnaround: 20-30 days

Our concours driveshaft restoration service is all inclusive, including return shipping anywhere in the lower 48 states. Send us your production original driveshaft components and you get back a complete concours correct driveshaft that's ready to install. This is not a driveshaft tube polishing service. We replace the tube with the same electro resistance welded seamed tubing the factory installed. This way we don't have to fake any finishes. The welds, bare steel blue seamed tube and the color of the blue heat rings on the spot welded balance weights all look real because... they are real. We believe the only way to properly restore a driveshaft is to break it down to its components, restore each component and then assemble it just like Ford did it. If you don't have your original driveshaft and/or don't know what the correct components are for your car see below.

Important: For our driveshafts to fit and function as they should your car needs to have its original drivetrain. If your car doesn't have its original drivetrain contact us before ordering.

Tapered 3.5" tube driveshafts: If your driveshaft came from the factory with a 3.5" tapered tube we can only replace it with thicker 3" non-tapered tube. It will be strong enough with its extra thickness but won't be concours correct.

Tube-in-tube driveshafts: if your car came with a tube-in-tube rubber insulated driveshaft we cannot restore your driveshaft. We can only replace it with a 3" tube and replace the small rear tube yoke with a 3" yoke.

Restoration Process:

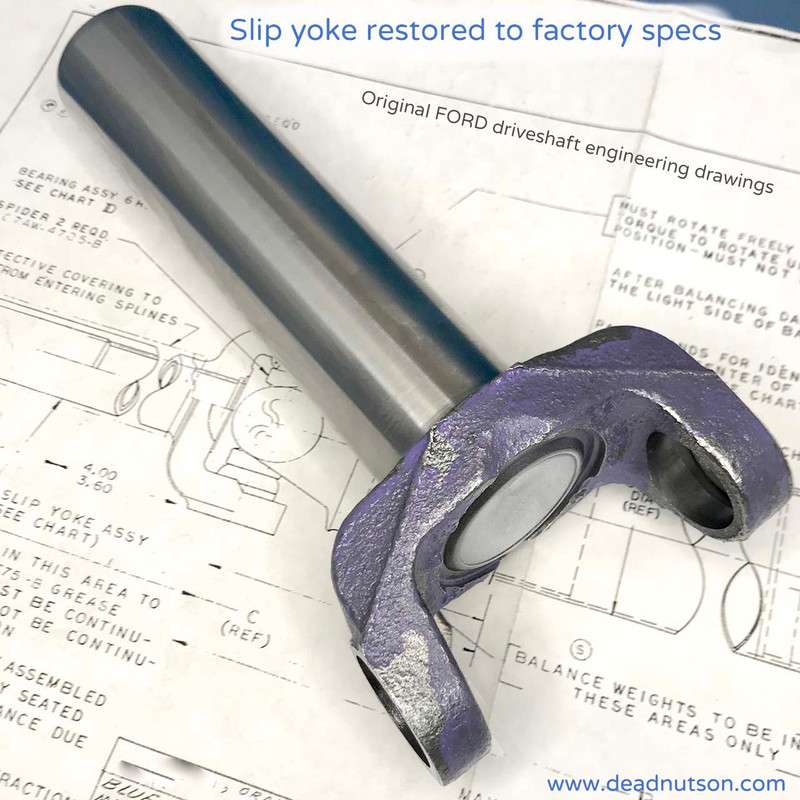

- Verify all components are within factory dimensional tolerances

- Verify all components are cosmetically acceptable for a concours quality restoration

- Transmission slip yoke refinished, paint coded, factory machined areas resurfaced including the barrel for a good seal

- Tube yokes refinished, paint coded and factory machined areas receive a fresh resurfacing

- Install our concours reproduction zerkless u-joints or your restored factory installed production zerkless u-joints

- Tube yokes welded to new 3 inch electro resistance welded blue seam driveshaft tube

- Install transmission slip yoke and balancing fixtures

- High speed balanced with factory rectangular spot welded balance weights

- Unique build sheet paint code stripes specific to your application sloppily applied like the factory did it (some concours correct codes are not available)

- Apply rust protection oil and wrap in special anti-corrosion paper

- Safely shipped via UPS back to your garage in our proven packaging system

Common Questions:

Q: When I send you my driveshaft cores do I get my parts back?

A: Absolutely, when your cores arrive they are photographed then tagged with your name so we can track them through the entire restoration. The cores you send in are the ones you will get back, guaranteed.

Q: I don't have cores, what do I do?

A: You have a couple of options. First check if we have any cores in stock (see below). Second, source the cores yourself using the identification guide below. Ford used driveline components that are found on many other high-production passenger cars so they are not that hard to find when you know what to look for.

Q: How do you polish the driveshaft tube to make it look like new?

A: We don't restore the tube. We replace it with the same electro resistance welded seamed tubing the factory installed. This way we don't have to fake the welds, bare steel finish, blue seam or the spot welded balance weights. Sanding and polishing reduces the already thin .065" tubing thickness that affects its strength so we never recommend polishing.

Q: I've modified my engine and it's now producing a little more than 500 HP. Will a stock driveshaft hold up to this extra power?

A: All our driveshafts now come with .083" driveshaft tubing vs the factory .065" thick tubing. This little extra thickness only adds a small amount of weight but adds a lot of strength. Tire stickiness and high rear axle gear ratios are what make driveshafts fail. Most street-driven cars have stock bias ply tires or street radials that will never hookup enough to put any significant load on the driveshaft. Our conservative rule of thumb is this: If your engine is producing over 600 HP at the crank or your running slicks this driveshaft may not be for you. Contact us if you have any questions.

Q: I'm restoring my Cobra Jet Torino to compete in a survivor classes. Will your reproduction u-joints pass in the these classes?

A: In these classes the judges deduct points for any part that isn't an original production line part. We suggest you use restored production line u-joints with the tiny faint Ford logo if they are within your budget. Although it's difficult to see that faint Ford logo when the u-joints are installed it's better to be on the safe side and use production originals.

Q: Still have questions?

A: Contact us and we'll answer them all.

HOW TO GET STARTED

STEP 1 Verify or source your driveshaft cores

Before you ship your driveshaft to us for restoration use the guides below to help verify you have the correct driveshaft components.

31 Spline Transmission Slip Yoke:

The 1970 and later transmission slip yoke was relatively common since it's the same slip yoke used behind most Ford passenger cars with a C6 transmissions from 1970 thru the late seventies. See links below for more help identifying the correct slip yoke and if we have any cores available.

PLAN B: If you cannot source a real 1970 production original slip yoke Ford made later versions that are more common and looked identical when installed. The 1973 and later production and service versions are found with the same or shorter barrel length, both will work. The shorter barrel version has the same spline length so they look the same when installed. Warning about the later short and long barrel slip yokes: The spline length inside the barrel can vary on later versions so make sure the spline length is no longer than 5 inches otherwise the splines will bottom out on the transmission output shaft.

If you end up purchasing a slip yoke from us we will refund or credit you $50.

28 Spline Transmission Slip Yoke:

The 197-71 long barrel 28 spline transmission slip yoke can be difficult to source if you don't have your original. It's difficult to source because the 28 spline with a 1330 series u-joint combination was only used in low production vehicles. See the links below to see what if you have the correct slip yoke.

- Picture with dimensions

- Check our stock of concours correct production originals

*If you end up purchasing a slip yoke from us we will refund or credit you $50.

PLAN B: If you cannot source a real 1970-71 production original long barrel slip yoke Ford made later versions with a shorter barrel length that are more common but looked identical when installed. The 1972 and later shorter barrel versions usually had the same length as the 1970-71 longer barrel versions so they will work perfectly. You can find these shorter barreled versions in 1972> 351C Thunderbirds and 302/351 Ford vans. The van slip yokes can have longer or shorter barrels and spline lengths so make sure the spline length is no longer than 5 inches otherwise the splines will bottom out on the transmission output shaft.

NOS slip yokes: NOS parts are service parts made to function like originals. They may or may not be exact copies of originals. Ford serviced the 1970 slip yoke for years with several versions that will function perfectly but may not look exactly the same the 1970 production slip yokes. If you would like us to use your NOS slip yoke send it in with your other cores and we will credit or refund you $50.

U-Joints:

The factory only installed zerkless 1330 series u-joints. Without grease zerks they were not easily serviceable so they were usually replaced during normal maintenance. We don't commonly see them in cars with more than 20,000 miles so don't be surprised if your car doesn't have its originals. We can supply your restored production originals if available or install our concours reproductions. NOS service u-joints are not usually an option since they have a completely different design and have grease zerks. With that said you can occasionally find production zerkless u-joints in Ford service boxes and also installed in a NOS driveshaft.

Tube Yokes:

The tube yokes, also known as weld yokes are the yokes, at both ends of the driveshaft tube. Ford used these tube yokes in passenger cars and trucks from 1967 thru the late '70s. These 1330 series 3 inch tube yokes are found on many Fords with larger displacement engines.

STEP 2 Print your order

Include a copy of your invoice or your contact information with your cores so we can reference your online order.

When your package arrives we will contact you after we inspect your cores. This may take a few business days so please be patient.

We will call or send you an email notifying you that your driveshaft restoration has been completed. The email will include UPS package tracking information so you can track it all the way to your door. A detailed invoice with warranty information will be included within the package.

STEP 6 Install your driveshaft and have fun

Your driveshaft will be fully assembled so all you'll need to do is remove the packaging and install it. If you choose to apply anti-rust protection or clear coat paint before installation we include a list of options and products we recommend.

Install Tip: The factory pinion yoke u-bolts torque specifications are only 14-17 foot pounds, otherwise you run the chance of causing premature wear on the u-joint cup bearings. As always, if you have any questions please contact us.

Hardware: If you don't have the concours correct driveshaft u-joint u-bolt hardware we stock the complete set.